Life

Distributions

Reliability

engineers are in many ways like soothsayers - they are expected to

predict many things for the semiconductor company: how many failures

from this and that lot will occur within x number of

years, how much of this and that lot will survive after x

number of years, what will happen if a device is operated under these

conditions, etc.

To many

people, such questions seem overwhelmingly difficult to answer,

half-expecting reliability engineers to demonstrate some supernatural

powers of their own to come up with the right figures.

Fortunately

for reliability engineers, they don't need any paranormal abilities to

give intelligent responses to questions involving failures that have not

yet happened. All they need is a good understanding of

statistics

and

reliability

mathematics

to be up to the task.

Reliability

assessment,

or the process of determining to a certain degree of confidence the

probability of a lot being able to survive for a specified period of

time under specified conditions, applies various statistical analysis

techniques to analyze reliability data. If properly done, a

reliability prediction using such techniques will match the survival

behavior of a lot, many years after the prediction was made.

A good

understanding of life distributions is a must-have for every reliability

engineer who expects to exercise sound reliability engineering judgment

whenever the need for it arises. A

life

distribution

is simply a collection of time-to-failure data, or life data, graphically presented as

a plot of the number of failures versus time. It is just like any

statistical distribution, except that the data involved are life data.

By looking at the

time-to-failure data or life distribution of a set of samples taken from

a given population of devices after they have undergone reliability

testing, the reliability engineer is able to assess how the rest of the

population will fail in time when they are operated in the field.

Based on this reliability assessment, the company can make the decision

as to whether it would be safe to release the lot to its customers or

not, and what risks are involved in doing so.

All new

engineers in the semiconductor industry are acquainted with the

bath tub

curve,

which represents the over-all failure rate curve generally observed in a

very large population of semiconductor devices from the time they are

released to the time they all fail. The bath-tub curve has three

components: the

early life

phase, the

steady-state

phase, and the

wear-out

phase.

The failure

rate is highest at the beginning of the early life phase and the end of

the wear-out phase. On the other hand, it is lowest and constant in the

long steady-state phase at the middle part of the curve. Collectively,

these phases make the curve look like a bath tub (where it obviously got

its name).

The bath tub

curve takes into account all possible failure mechanisms that the

population will encounter. Some failure mechanisms are more

pronounced in the early life phase (such as early life dielectric

breakdown), while others are more pronounced in the steady-state or

wear-out phases. Failures that occur in the early life phase are known

as

infant mortality,

which are screened out in production by burn-in.

In real life,

it is not always practical to evaluate the failure or survival rate of a

population of devices in terms of the bath tub curve. Reliability

assessments are often conducted to evaluate only the known weaknesses of

a given lot or, if the lot has no known weaknesses, to determine if it

is vulnerable to any of the critical failure mechanisms dreaded in the

semiconductor industry today.

Such

reliability assessments are conducted by running a set of

industry-standard reliability tests, generating life data along the way.

These life data are then analyzed according to what type of life

distribution they fit.

There are

currently

four (4) life

distributions

being used in semiconductor reliability engineering today, namely, the

normal distribution, the

exponential distribution, the lognormal distribution,

and the Weibull distribution.

Different failure mechanisms will result in time-to-failure data that

fit different life distributions, so it is up to the reliability

engineer to select which life distribution would best model the failure

mechanism of interest.

Life distributions are

described mathematically by

life distribution functions. Three of

these functions are very important descriptors of life distributions,

and should be understood by every reliability engineer. These are

the

cumulative failure distribution function F(t), the failure probability density function f(t), and the curve of failure rate

l(t).

The

cumulative

failure distribution function F(t),

or simply cumulative distribution function,

gives the probability of a failure occurring before or at any time, t.

This function is also known as the unreliability function. If a

population of devices is operated from its initial use up to a certain

time t, then the ratio of failures, c(t), to the total number of devices

tested, n, is F(t). Thus, F(t) = c(t)/n. F(t) is therefore always

less than 1, which is consistent with the fact that it's just a

probability number after all.

The

unreliability function F(t) has an equivalent opposite function - the

reliability function R(t). R(t) = 1 - F(t), so it simply gives the

ratio of units that are still good to the total number of devices after

these devices have operated from initial use up to a time t.

The

failure probability density

function f(t),

or simply probability density function,

gives the relative frequency of failures at any given time, t. It

is related to F(t) and R(t) by this equation: f(t) = dF(t)/dt = -dR(t)/dt.

The

curve of failure rate

l(t),

also known as the failure rate function or the hazard function, gives the instantaneous failure rate at any given

time t. It is

related to f(t) and R(t) by this equation:

l(t)

= f(t)/R(t). Thus,

l(t)

= f(t)/[1-F(t)].

More details

on how these functions describe the various life distributions may be

found at

Life Distribution Functions.

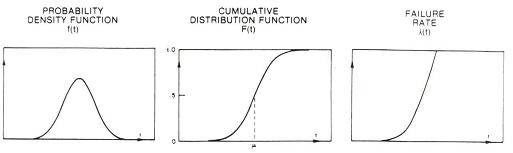

The Normal

Life Distribution

A

normal life distribution

is one that consists of time-to-failure or life data that constitute a

normal distribution. Thus, it is a

symmetric bell-shaped curve whose mean, median, and mode are equal.

The spread of the normal life distribution is determined by the standard

deviation

s

of its life data. The failure rate of a normal life distribution

monotonically increases with time, which is failure rate pattern

typically exhibited by failures due to

wear-out.

Normal

distributions are often a result of the

additive

effects of

random

variables. Thus, normal life distributions are generally applicable to

failures that are affected by additive factors, such as mechanical

system failures that occur as a result of the accumulation of small and

random mechanical damage. Such mechanical failures are often

observed as the system wears out with use.

Figure 1.

The f(t), F(t), and

l(t)

of a normal life distribution; source: D. S. Peck and O. D. Trapp,

Accelerated Testing Handbook, Technology Associates.

We all know

that the over-all failure rate of semiconductors do not increase

monotonically with time. In fact, there aren't too many

semiconductor failure mechanisms that fit the normal life distribution.

Thus, the

normal

life distribution is generally

not

used by reliability engineers to model semiconductor survival in the

field.

Note,

however, that the bath tub curve representing the failure rate

curve of semiconductor devices does include a wear-out phase in the end.

This

wear-out phase,

although just the end portion of a semiconductor's life, may be modeled

by a

normal

life distribution.

The

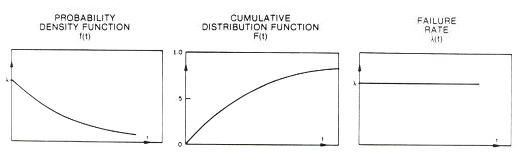

Exponential Life Distribution

An

exponential

life distribution

is one wherein the failure rate is constant in time. The exponential

life distribution is best applied to the analysis of failures in the

steady-state

phase of the bath tub curve, during which the failure rate is constant.

Other than this, reliability engineers don't use the exponential life

distributions a lot, because there are not too many

frequently-encountered critical failure mechanisms that exhibit this

life distribution.

Figure 2.

The f(t), F(t), and

l(t)

of an exponential life distribution; source: D. S. Peck and O. D. Trapp,

Accelerated Testing Handbook, Technology Associates.

The

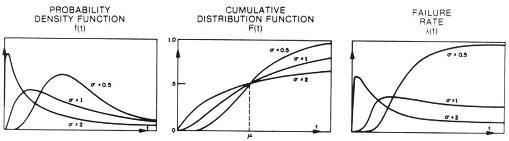

Lognormal Life Distribution

The

lognormal

life distribution

is one wherein the natural logarithms of the lifetime data, ln(t), form

a normal distribution. Consequently, the life data of a lognormal

distribution will also form a straight line if plotted on a

lognormal

plot, i.e., a plot whose x- and y-axes stand for the cumulative % of

failures and the logarithmic scale of time, respectively. The

failure rate curve

l(t)

of a lognormal life distribution starts at zero, rises to a peak, then

asymptotically approaches zero again for all values of

s.

The lognormal

distribution is formed by the

multiplicative

effects of random variables. Multiplicative interactions of variables

are found in many

natural

processes, and are in fact observed in many frequently-encountered

semiconductor failure mechanisms. This characteristic of the

lognormal distribution makes it a

good

choice for the analysis of the failure rates of many semiconductor

failure mechanisms.

A notable

characteristic of the lognormal distribution is the fact that its median

time to failure, t50%, or the time at which 50% of the

samples fail, is equal to eµ, where µ is the mean of the life

data. Thus, t50%

= eµ.

Figure 3.

The f(t), F(t), and

l(t)

of a lognormal life distribution; source: D. S. Peck and O. D. Trapp,

Accelerated Testing Handbook, Technology Associates.

The

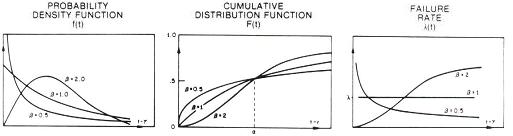

Weibull Life Distribution

The

Weibull life

distribution

was developed by W. Weibull of Sweden to investigate metal fatigue

failures. It is described by a location parameter

a

and a shape

factor

b,

and is similar to the lognormal distribution in many ways. Two of the

major differences between them are: 1) the Weibull distribution's

probability density function does not start from zero; and 2) its

failure rate curve

l(t)

is monotonically increasing for

b

> 1 and

monotonically decreasing for

b

< 1.

The Weibull

distribution can take on many shapes, depending on the value of the

shape factor

b.

In fact, by varying the value of

b,

all the phases of the bath tub curve can be modeled by the Weibull

distribution. The

early life

phase, wherein the failure rate decreases with time, can be represented

by the Weibull distribution with

b

< 1.

The

steady-state

phase, wherein the failure rate is constant, can be represented by the

Weibull distribution with

b

= 1.

Finally,

letting

b

be > 1

will make the Weibull distribution a model for the

wear-out

phase,

wherein the failure rate increases with time.

Figure 4.

The f(t), F(t), and

l(t)

of a Weibull life distribution; source: D. S. Peck and O. D. Trapp,

Accelerated Testing Handbook, Technology Associates.

The Weibull

distribution has become popular in reliability engineering, partly

because of its simpler math and flexibility, and partly because earlier

works using this distribution have found it to fit some failure

mechanisms nicely. A closer look at the same mechanisms showed

that they, too, fit the lognormal distribution.

Thus, the

lognormal distribution should have been a better choice in the first

place since its mathematics are consistent with the physical phenomena

taking place. Care must therefore be taken when an engineer sees data

fitting the Weibull distribution, since they can turn out to be

lognormal in reality.

Please

see Life Distribution Functions for

more detailed mathematical descriptions of these life distributions.

See also:

Reliability

Engineering;

Life Dist. Functions; Lognormal Plots; Reliability

Modeling; Failure

Analysis; LTPD/AQL Sampling

HOME

Copyright

© 2004

EESemi.com.

All Rights Reserved.