Package-on-Package

(POP)

Package-on-Package

(POP),

as its name implies,

is a semiconductor packaging innovation that involves the stacking of

two or more packages on top of one another. Signals are routed

between the packages through standard package interfaces.

Obviously, one advantage of this vertical combination of different

packages is board space savings. POP is a good packaging solution

for applications that require more features in less space, such as

digital cameras, PDA's, MP3 players, and mobile gaming devices.

POP assemblies

today usually consist of just two packages, such as a memory device

mounted on top of a logic device. Most companies that are developing POP

assembly capabilities are leveraging well-established assembly processes

and infrastructure (such as those used in CSP, BGA and flip-chips), so

that little or no development will be required for the top package.

The bottom or base package may likewise employ die stacking in order to

allow the combination of analog functionality or flash memory to the

logic chip.

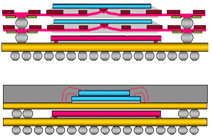

Figure 1.

Examples of Package-on-Package (POP) Structures

source of

original images:

www.akita-elec.co.jp

According to

Amkor's website, POP is an enabling technology that offers the following

benefits: 1) it provides OEM's and EMS with a platform for

effective 3-D integration of logic and memory; 2) it simplifies

the business logistics of stacking; 3) it allows integration control at

the system level, thereby facilitating the optimization of stack

combinations; 4) it eliminates margin stacking and expands technology

reuse; 5) it helps mitigate the impact of high costs usually associated

with multimedia processing; and 6) it makes mass customization of

systems for various usage requirements possible. Figure 1 shows an

example of a package-on-package (POP) structure.

As of this

writing (2006), the top package of a typical POP may have an I/O

interface consisting of hundreds of pins, with an I/O pitch of 0.65 mm.

The industry may soon move to 0.5 mm pitch though. The bottom

package of a typical POP employs a finer I/O pitch, i.e., it currently

uses a pitch of 0.5 mm that may soon be replaced by a 0.4 mm pitch.

Wafer thinning is an essential part of POP assembly, in order to make up

for the increased height requirements of vertical integration. POP

package heights of 1.2 mm to 1.6 mm are now available in the industry in

various configurations.

See Also:

CSP;

Ball Grid Array;

Flip Chip; Die Stacking

HOME

Copyright

©

2005

www.EESemi.com.

All Rights Reserved.