Test

Equipment Accessories

Contactors and Loadboards

High-volume electrical

testing of integrated circuits requires an

Automated Test Equipment

(ATE)

in

conjunction with a

test handler. ATE/handler

systems, however, are generic pieces of equipment that need to undergo

final configuration to make them suitable for use on devices they are to

test.

Accessories needed to configure an ATE for

production use include the right

contactors

to match the package of the devices under test (DUT's),

family boards

to match the ATE to the product group where the DUT's belong, and

loadboards,

interface boards,

or

DUT boards

to configure

the ATE to match the test requirements of a

specific device (or a specific group of devices).

Just as semiconductor

package outlines come in all forms and sizes, so do the

contactors or

contactor assemblies that cater to each of them. A contactor is a mechanism with a

set of contact elements usually in the form of metal fingers (also known as

'contact fingers') or spring-loaded

pins that come into contact with the leads or solder balls of the DUT

during electrical testing. Before production testing can begin, the test

handler must first be fitted with the test contactor assembly or

contactor block suitable

for the device to be tested.

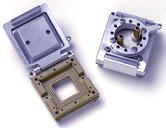

Fig. 1.

Examples of ATE Contactors

The term 'contactor'

may also refer to

sockets employed to get convenient electrical

access to the DUT, especially if the DUT is a fine-pitch, high-pin count

complex device. Sockets are often used for hand-testing of DUT's

or in failure analysis.

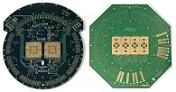

Load

boards, DUT boards, and interface boards may all refer to the

same thing - a circuit board used to provide the special test circuits

needed to set up a DUT for proper ATE testing. They are boards that interface between the ATE and the DUT,

so in a way they may be considered as matchmakers between the two.

Load boards or DUT boards can also be designed for hand testing.

Hand-testing load boards have a socket for manual loading and unloading

of the DUT instead of the cable that goes to the contactor assembly of

the handler.

|

|

Fig. 2.

Examples of ATE Load Boards |

Companies

with a large portfolio of products also use

family boards,

which are basically 'large' load boards that provide the 'common' test

circuitries needed by a product family, say, ADC's. The family

board goes into the ATE, while the DUT or load board goes into the

family board, acting as a daughter card to the family board. The

DUT board or load board further customizes the test circuits to the specific

requirements of the DUT. Family

boards and DUT boards contain all the necessary components to: 1) set

up the DUT for correct testing by the ATE; 2) route

the test and response signals between the DUT and the ATE; and 3)

provide additional test capabilities that the ATE may not be able to

provide.

Test Head

Manipulators and Docking Systems

Modern ATE systems have a

large test head

that needs to interface with the handler system. Test heads are

oftentimes too bulky for easy manipulation, so the test technician needs

what is known as a test head

manipulator or

positioner

for easier handling of the test head during the interfacing process.

Fig. 3.

Examples of Test Head Manipulators

Test head manipulators are basically mobile frame structures designed to

hold and position ATE test heads for

docking

with a test handler, consisting of a system of wiring conduits with

several axes of manipulation, counter-weighing mechanisms, and powered

or manual gearing. Manipulators must be stable, reliable, and quick to

set up.

Today's trend toward bigger, more capable test heads requires

state-of-the-art manipulators that are more than just strong. The test

head bundles are becoming more rigid and delicate, requiring more wiring

and cooling conduits. Operators must be given

more control

of the test head during the docking and undocking process. Thus, a

good manipulator also addresses the need for critical cable management

and smooth handling, while independently controlling linear and rotational

motions. Ease of docking and protection of delicate electrical interface

components are a must.

Aside from test head

manipulators, modern ATE systems and handlers also need a

'docking' system

in order to interface with each other. Years ago, ATE systems get

interfaced to a handler just through cables and connectors. Although

this is a cheap way to get the ATE talking to the handler, it has some

major disadvantages: 1) it can become disorderly and more difficult to

set up; 2) it results in RF losses; 3) it is notorious for intermittent

or poor contacts; and 4) it is inadequate for complex ATE/handler

systems.

Today's highly

competitive semiconductor testing industry requires not just a quick and

convenient process for interfacing an ATE to a handler, but also a way

to interface any tester to any handler. A universal, adjustable

docking system is the answer to these needs.

Fig. 4.

Examples of Docking Systems

A docking system

(see Fig. 4)

is a test equipment accessory that mechanically connects the test head

of an ATE to the handler, providing a robust, stable, and accurate

interface between the ATE and the handler. By employing a standard and

carefully selected docking system on the test floor, tester and handler

interchangeability may be achieved to boost flexibility and

productivity.

See Also:

Test Equipment;

Contactors; Load Boards;

Electrical Testing;

IC

Manufacturing

HOME

Copyright

©

2005.

EESemi.com.

All Rights Reserved.